Methodology

Framework of our projects and variations

Experience demonstrates that it is entirely unrealistic to apply a singular methodology to all projects. A genuine approach to innovation necessitates methodological adaptation for each individual project.

This adaptation takes different forms:

– Selecting methods for each stage: from observation techniques to analysis methods and creativity tools…

– Scaling each stage to ensure we deliver results while keeping within budget.

– Incorporating cross-disciplinary aspects: handling legal, technical, and marketing issues to enhance the process (see Who we are / Our cross-disciplinary vision).

– Iterative approaches at the core of phases, without deciding the number of iterations beforehand, sometimes even across two phases, like creativity and experimentation.

The presentation below provides a simplified perspective to enhance comprehension

To deeply engage with the user

Observe, Objectify, and Extract Key Insights

Identify, qualify, and prioritize issues to initiate innovation on solid foundations.

Write the product narrative and design the packaging that conveys this story.

Turn a concrete solution into an economic reality through medium or large-scale manufacturing

Validate milestones, refine concepts through physical solutions

Test the final solution in the lab or in the field through an official protocol

1. Observe

We implement in vivo observations of patients or healthcare professionals. The designer is placed directly in the user’s environment to fully understand the conditions of use and develop fitting solutions.

Benefits: Objectivity and extraction of constraints and key insights.

Examples :

Observing the use of radiological systems.

Interviews and observations with patients suffering from polyarthritis.

2. Analyse

The documentation and information gathered during the observations are subject to a thorough analysis.

Ergonomics, functional constraints, and usage scenarios are studied and then synthesized into an Ergonomic Design Brief.

Benefit: The innovation project is built on a solid foundation.

Examples:

Exploring the physiological rationale behind a physiotherapy treatment.

Analysis of postures and grips involved in a surgical procedure.

3. Create

Creative meetings rely on thorough preparation: arranging the space to reflect usage conditions, preparing materials and tools for brainstorming, selecting an appropriate method, and delivering a focused kickoff briefing. Day-to-day creativity is also fostered through spontaneous short meetings to tackle arising issues.

Benefit: A tailored approach to meet needs and challenges.

Examples:

Concept creation workshop utilising samples.

Working session led by a designer, concept screening.

4. Experiment

Concepts are roughly modeled to experiment and steer the design process. Early prototypes are then progressively developed to facilitate evaluations with users at the earliest opportunity.

Benefit: Testing creativity against the realities of usage.

Examples:

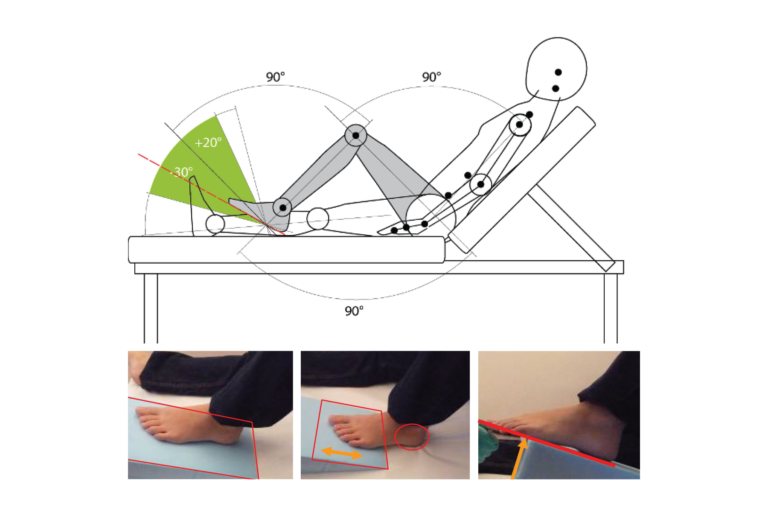

A client testing a research prototype for ankle mobilisation.

A nurse exploring the optimal way to apply a cuff under development.

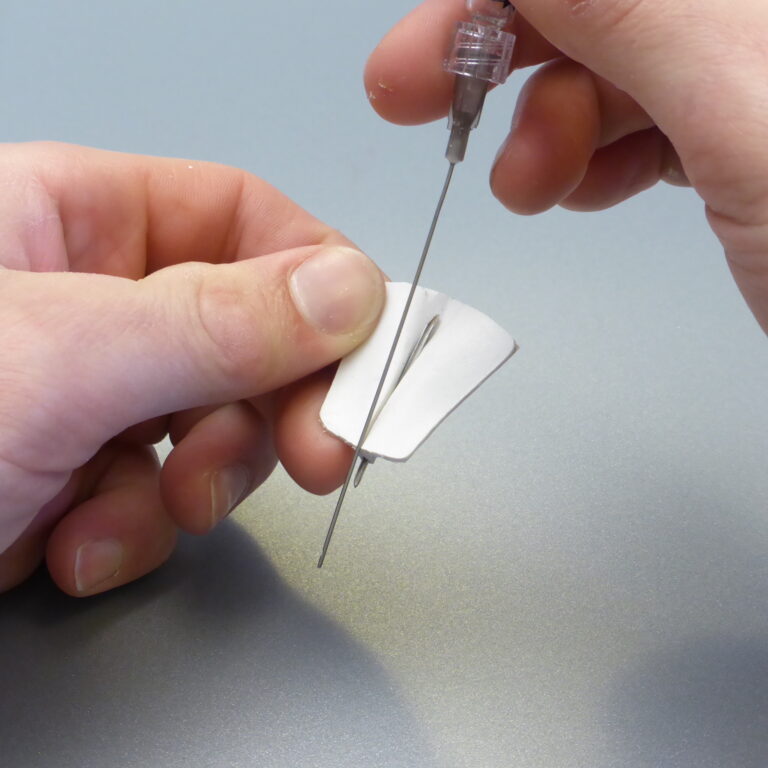

A user evaluating different auto-injector concepts.

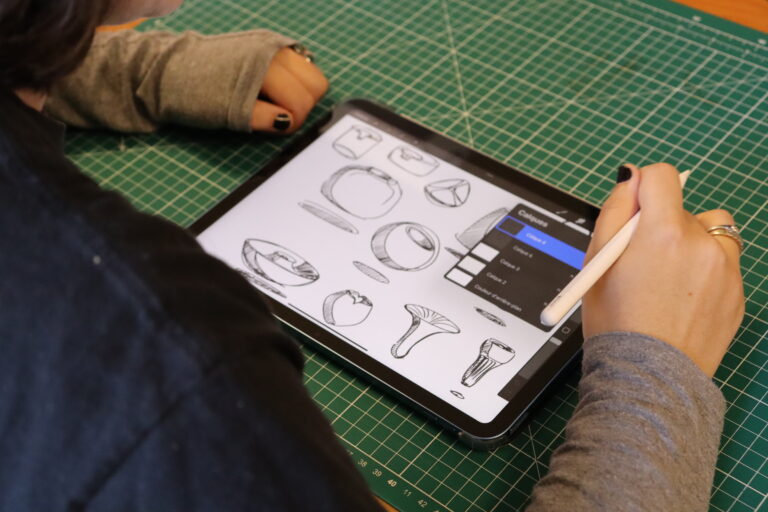

5. Design

Convey the brand’s values, define the solutions and features to create a device that excels in ergonomics, ease of use, and aesthetics.

Benefit: A Global Design approach to reconcile all constraints.

Examples:

Creation of a visual and semantic universe that embodies the product and brand values.

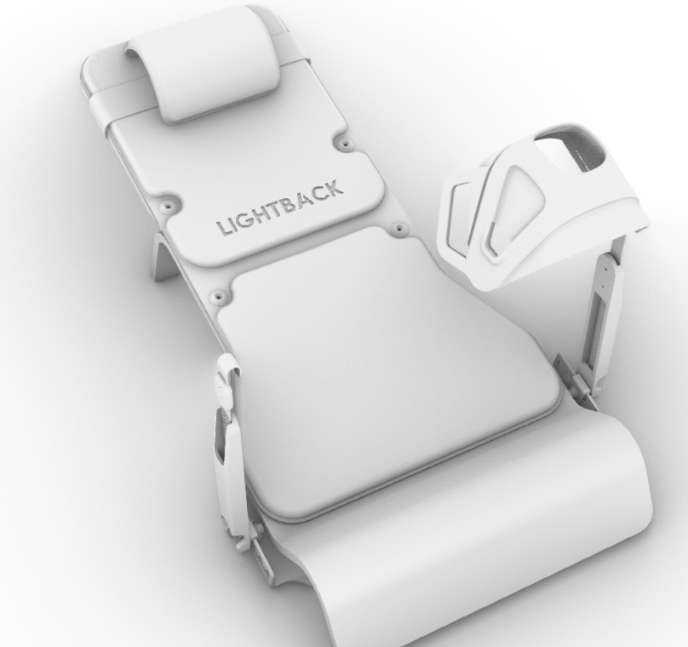

Overall design of the device, incorporating ergonomic considerations.

6. Verify

The prototype is presented to users in order to inform the next phase of the study and potentially differentiate between multiple versions. If required by the context, this study phase will be part of the device’s regulatory usability process (formative study according to IEC 62366 standard).

Benefit: Evaluate the relevance of concepts within a regulatory framework.

Examples:

Exploration of options for an ankle mobilization device.

Testing in an NBC (Nuclear, Biological, Chemical) emergency context.

Auto-injector testing in collaboration with CIC-IT Evalab (CHRU Lille).

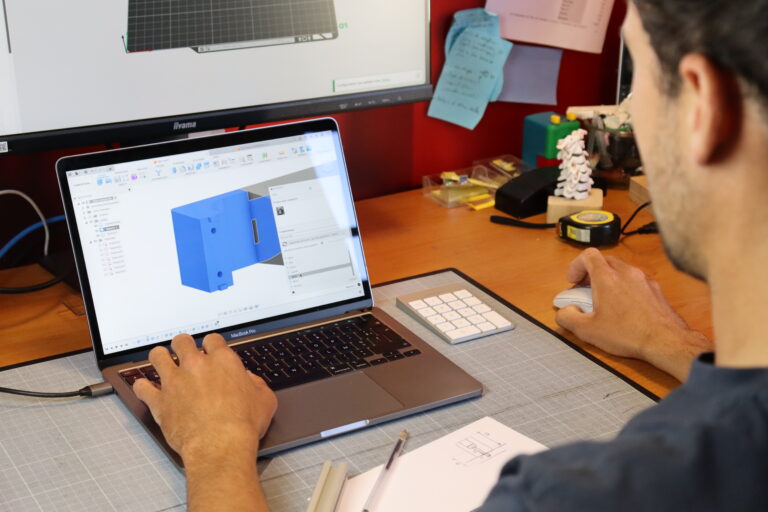

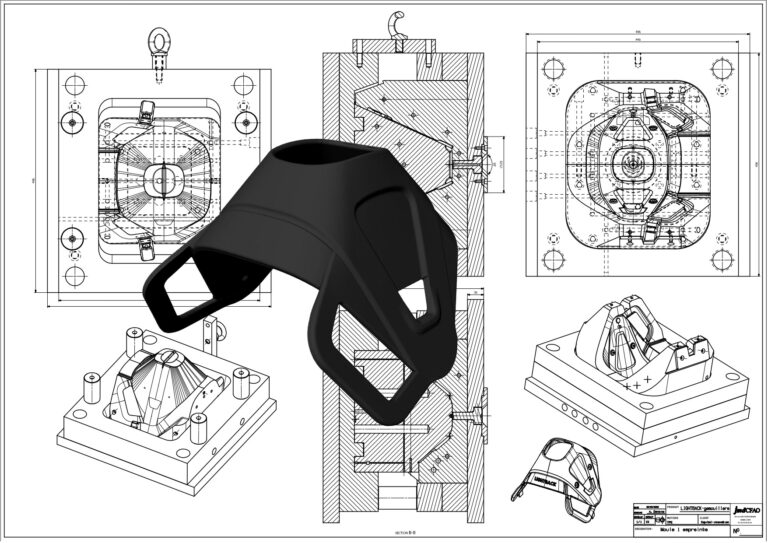

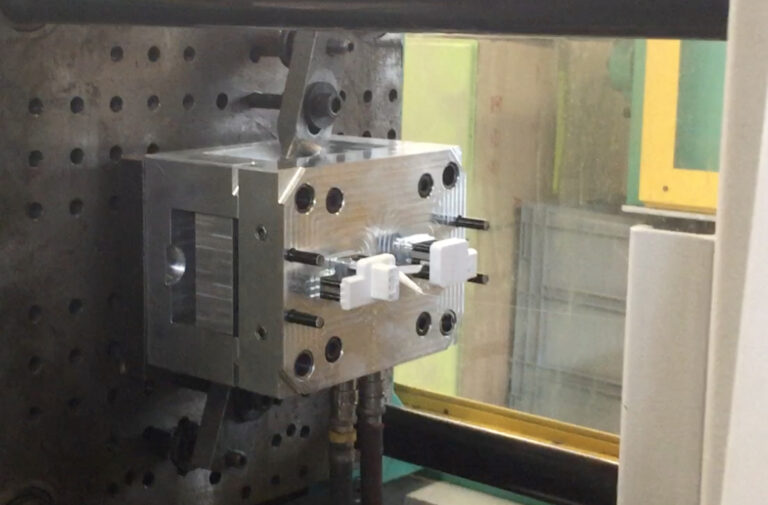

7. Scale up for industrial production

Initiate a dialogue with the industrialisation team to ensure their full involvement and the successful completion of the project. Support the client through to market launch.

Benefit: Ensure the project is completed under the best possible conditions.

Examples:

Preparation of documents for industrial consultation.

Assistance in finding suppliers and evaluating technical proposals.

Exchange on plastic materials and decisions regarding construction and assembly methods.